XMQ棒磨機(jī)適用于實(shí)驗(yàn)室濕法磨細(xì)礦石或其他物料之用。也可以將鋼棒換為鋼球作球磨機(jī)使用。但棒磨時(shí),磨細(xì)產(chǎn)物粒度組成較均勻,過粉碎現(xiàn)象較小,且效率較高。一般進(jìn)行礦石可選性實(shí)驗(yàn)研究和人工重砂磨細(xì)礦石時(shí),宜采用棒磨。本產(chǎn)品由原地礦部唯一指定企業(yè)生產(chǎn),執(zhí)行行業(yè)標(biāo)準(zhǔn)。

XMB Rod Mill is applicable to lab. for wet fine grinding of ore and other materials. Steel ball may be used instead of steel rod in the ball mill. In rod grinding, fine product particle fractions are relatively uniform with rare occurrence of overgrinding and high efficiency. In general, rod grinding is introduced for test on ore for separability and manual fine grinding of placer materials. The product is produced by the only enterprise designated by the former Ministry of Geology and Mineral Resources, in compliance with the Industrial standards.

球墨鑄鐵筒體與大皮帶輪用螺釘聯(lián)為一體。筒體一端為開口,另一端為空心軸頸;兩端分別承在一對(duì)托和一個(gè)主軸承上。主軸承座和托架,分別裝在可轉(zhuǎn)支180°的支承板上。支承板用兩個(gè)軸承軸承座裝在機(jī)架上。支承通過回轉(zhuǎn)操縱手把及定位板,可以從水平左右偏轉(zhuǎn)用22.5°、6735°、及90°,以完成裝礦、排礦、倒棒和充滿防銹石灰水等動(dòng)作。

Drum of spheroidal graphite cast iron and big belt pulley are connected through screws. At one end of the drum is an opening and at the other end of it is a hollow journal. Both ends are respectively supported on a pair of rollers and a main bearing. The main bearing seat and bracket are respectively on the bearing plate which can rotate for 180°. The bearing plate is installed on the frame with two bearing pedestals. The bearings control the handle and positioning plate through rotation. Horizontal deflection of 22.5°, 6735° and 90°can be applied to realize ore loading, ore discharging, tamping rod, filling antirust limewater, etc.

筒體右端有給礦口塞。械端有排礦口蓋;工作時(shí),用一時(shí)專門板手,按順時(shí)針方向擰緊螺栓,使排礦口蓋上的密封橡膠墊緊螺栓三、四轉(zhuǎn)使蓋子向外退出工6~10毫米,不用將蓋子取下即可排礦。在排礦口端安設(shè)了集漿罩。在設(shè)計(jì)工作轉(zhuǎn)速內(nèi)完全消除子轉(zhuǎn)支清洗時(shí)礦漿飛濺的現(xiàn)象。

There is plug of feed mouth on the right of the drum and there is cover of discharge mouth at the end of the machine. During the operation of the machine, use a special-purpose spanner to tighten the bolts, to get the sealing rubber gasket on the cover of discharge mouth to tighten the bolts for three or four rounds so that the cover can go backward for 6~10mm. Ores can be discharged without the cover being removed. At the end of the discharging mouth is installed a slurry cover, which completely avoid splashing of slurry during the washing rotating branch within the designed working speed.

電機(jī)及中間軸裝在支承下面,以便與上部的重量配置均衡。傳動(dòng)的兩級(jí)皮帶每級(jí)均可調(diào)節(jié)皮帶松緊,以保證全適的磨礦工作轉(zhuǎn)速。

The motor and intermediate shaft are installed below the bearings, so as to realize balance with the weight above. The tension of belt can be adjusted for every grade of the driving two-grade belt pulley, to ensure appropriate grilling speed.

67型棒磨機(jī)的皮帶調(diào)整,是由支承板上T型槽滑道和中間軸座板上的長(zhǎng)分別進(jìn)行。

The pulleys of 67 rod mill are respectively adjusted through the T-groove slide on the supporting plate and the slot on the seat board of the intermediate shaft.

68型棒磨機(jī)的皮帶調(diào)整,按下述方法進(jìn)行:

The pulleys of 68 rod mill are respectively adjusted according to the following method:

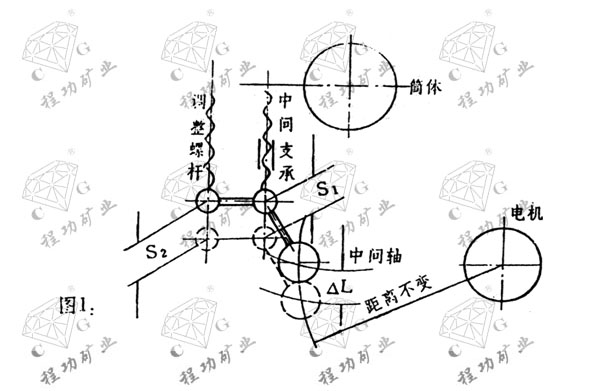

1、筒體皮帶的調(diào)整:主要是調(diào)節(jié)中間支承的上下位置。但為了不致景響電動(dòng)機(jī)皮帶的松緊,須對(duì)調(diào)整螺桿作相應(yīng)的調(diào)整(圖1)。

1. To adjust drum belt, what should be done mainly includes the adjustment of vertical position of intermediate support. However, in order not to affect the tension of motor belt, corresponding adjustment shall be made of the adjusting bolt (Figure 1).

△L—需要調(diào)整量(圖示需調(diào)緊)

△L — Required adjustment amount (needing to tighten as is shown in the figure)

S1—中間支承調(diào)整量(圖示向下)

S1 – Adjustment amount of intermediate support (moving downward as is shown in the figure)

S2 —調(diào)整螺桿調(diào)整量(圖示向下)

S2 – Adjustment amount of adjusting bolt (moving downward as is shown in the figure)

2、電動(dòng)機(jī)皮帶的調(diào)整:主要是調(diào)節(jié)調(diào)整螺桿的上下,使中間軸繞中間支承轉(zhuǎn)支一定位置。而為了不致影響筒體皮帶的松緊。須對(duì)中間支軸承相應(yīng)的調(diào)整,進(jìn)行補(bǔ)償。(圖2)

2. To adjust motor belt, what should be done mainly includes the adjustment of vertical position of screw, to get the intermediate shaft to revolve around intermediate support to a certain position. However, in order not to affect the tension of drum belt, corresponding adjustment shall be made of the intermediate shaft for compensation (Figure 1).

筒體:Drum

調(diào)整螺桿:Adjusting bolt

中間支承:Intermediate support

中間軸:Intermediate shaft

距離不變:Unchanging distance

電機(jī):Motor

△L—需要調(diào)整量(圖示需調(diào)緊)

△L — Required adjustment amount (needing to tighten as is shown in the figure)

S1—中間支承調(diào)整量(圖示向下)

S1 – Adjustment amount of intermediate shaft (moving downward as is shown in the figure)

S2 —調(diào)整螺桿調(diào)整量(圖示向下)

S2 – Adjustment amount of adjusting bolt (moving downward as is shown in the figure)

為適應(yīng)多種接礦容器的使用,折疊式接礦滑架,可以上下升降使用。機(jī)器的電器均已安裝好,接上電源和地線,即可按使用要點(diǎn)開車運(yùn)轉(zhuǎn)。

To match the use of various kinds of receiving containers, folding receiving carriage can move upward or downward. The electric equipment of the machine has been installed. When the power and earth wire are connected, the machine can be operated according to instructions.

| 型號(hào)規(guī)格 Model | 單位 Uite | XMQ160×200 | XMQ200×240 | XMQ240×300 | ||||||||

| 筒體尺寸 Drum size | mm | Ф160×200 | Ф200×240 | Ф240×300 | ||||||||

| 容積 Volume | L | 4.02 | 7.5 | 13.57 | ||||||||

| 磨礦量 Capacity | g | 300~800 | 500~1000 | 1000~5000 | ||||||||

| 給礦粒度 Feed size | mm | ≤2 | ≤2 | ≤3 | ||||||||

| 產(chǎn)物粒度 Particle size | mm | ≤0.074 | ≤0.0 74 | ≤0.074 | ||||||||

| 筒體轉(zhuǎn)速 Drum speed | r/min | 120±2 | 110±2 | 96±2 | ||||||||

| 電機(jī)功率 Power | kw | 0.25 | 0.55 | 0.55 | ||||||||

| 磨礦 介質(zhì) |

鋼棒 | 直徑 | mm | 18 | 20 | 15 | 18 | 22 | 15 | 18 | 22 | |

| 長(zhǎng)度 | mm | 185 | 225 | 286 | ||||||||

| 數(shù)量 | (根) | 10 | 9 | 17 | 9 | 9 | 33 | 13 | 6 | |||

| 重量 | kg | 3.55 | 4.09 | 4.9 | 4.2 | 4.9 | 12.79 | 7.48 | 5.02 | |||

| 鋼球 | 直徑 | mm | 20 | 25 | 30 | 20 | 25 | 30 | 20 | 25 | 30 | |

| 數(shù)量 | (個(gè)) | 100 | 26 | 5 | 136 | 52 | 29 | 290 | 115 | 37 | ||

| 重量 | kg | 3.31 | 1.70 | 0.56 | 4.4 | 3.3 | 3.7 | 9.57 | 7.37 | 4.1 | ||

| 外形尺寸 Overall dimensions | mm | 1052×530×1160 | 1052×615×1160 | 1052×615×1160 | ||||||||

| 重量 Weight | ㎏ | 90 | 155 | 160 | ||||||||